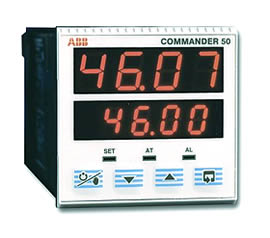

ABB CM50 Universal Process Controller 1/2 DIN

The ABB CM50 ControlMaster is a highly versatile, universal 1/2 DIN PID process controller. Detailed process information is presented clearly on the CM50’s full-colour TFT display and an intuitive operator interface simplifies configuration and operation.

Highly scalable in both hardware and software functionality, an ABB CM50 can be easily specified to meet the needs of virtually any process control application – simple or advanced. Powerful control functions such as adaptive control, math, logic and totalisation provide problem-solving flexibility and make the ABB CM50 suitable for a wide range of process applications.

Fully configurable via the easy-to-navigate front panel menus or PC configuration software, the ABB CM50 can be commissioned rapidly and then tuned via the advanced autotune capability.

MODBUS, PROFIBUS and Ethernet communication options ensure easy integration into a control system.

ABB CM50 Features

- Comprehensive display of process status

- Crystal-clear, full-colour TFT display

- User customisable

- Historical trending

- Exceptionally easy to use

- Intuitive user interface and clear text prompts make installation, commissioning and operation quick and simple

- PC Configuration

- Time saving off-line software tool including report generation

- Profile control

- Comprehensive setpoint profiling capabilities

- Powerful control functionality

- Cascade, feed-forward, ratio, predictive and adaptive control strategies

- Dual-loop capability

- Problem-solving capability

- Flexible functionality including math and logic providing power to solve application requirements

- Built to survive

- IP 66 and NEMA 4X environmental protection

ABB CM50 Powerful Operator Display

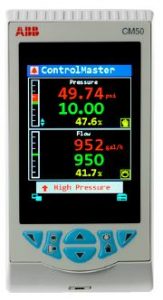

The ABB CM50 features a full-colour 9 cm (3.5 in.) display for displaying detailed process information to the user. Process details such as alarm messages and diagnostic information are displayed clearly in full text without the need for difficult to-read scrolling displays.

Example of an operator page

Automatic selection of standard display templates immediately makes best use of the CM50’s display. Extensive customisation features then enable the displayed information to be tailored to suit the process requirements.

Diagnostics and alarm status display

The diagnostics and alarm status display provides detailed information on any active alarm or diagnostic condition. The operator can see, at-a-glance, the status of any alarm condition present within the process.

Additionally, diagnostic messages are presented clearly to the operator, enabling rapid notification and simple diagnosis of any critical instrument status condition.

Historical information of diagnostic messages can also be viewed in the controller’s diagnostic log.

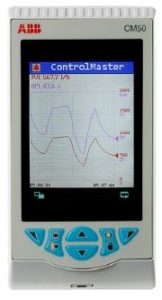

Trend display

Any two analogue values within the ABB CM50 can be plotted on the trend display to give a short-term process history.

This feature enables control efficiency to be monitored against setpoint and assists in tuning during commissioning.

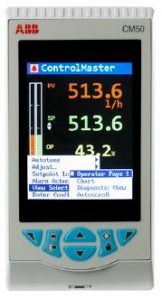

Exceptionally easy to use

The CM50’s full text display and simple-to-navigate, pop-up menus makes operation exceptionally easy.

The CM50’s full text display and simple-to-navigate, pop-up menus makes operation exceptionally easy.

A programmable soft key enables commonly used functions, such as alarm acknowledgement and display selection, to be accessed easily by the operator.

ABB CM50 Advanced control functionality

The ABB CM50 features many advanced control functions providing the power to bring even the most complex process under control.

Autotune

Once initial configuration is complete, a powerful autotune facility enables automatic calculation of the PID values required, enabling rapid commissioning of the CM50.

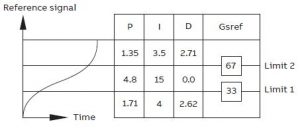

Gain scheduling

Gain scheduling

The CM50’s gain scheduling functionality is used for efficient control of non-linear processes.

Up to 3 different sets of PID parameters are selected automatically from a reference signal ensuring optimum control response, regardless of the process status.

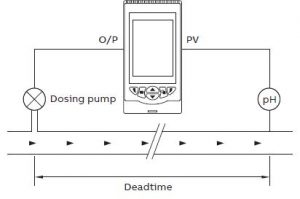

Predictive control (dead-time compensation)

Predictive control (dead-time compensation)

Control of processes with long dead-times, such as pH dosing in a pipeline, is addressed easily using pPI control.

Configured via only 3 parameters (gain, integral time and dead-time), pPI control can also be combined with gain scheduling for optimum control efficiency.

Adaptive control

Adaptive control enables the ABB CM50 to adjust its control response automatically to suit changing process dynamics. This makes the ABB CM50 particularly useful for processes with varying or uncontrolled types of load, by providing continuous tuning to maximise control efficiency.

The diagram (right) shows a product used in a manufacturing process that is stored in an outside tank. The use of adaptive control within the manufacturing process compensates automatically for the change in product temperature caused by seasonal variation.

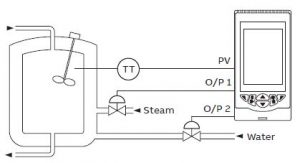

Split output control

The CM50 can also be configured to perform split output control, for example, when both heating and cooling of a single process is required.

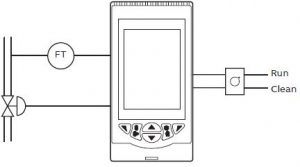

Remote auto / manual switching

Remote auto / manual switching

In addition to switching via the front panel, the CM50 can be switched between automatic and manual control mode using an external signal.

When switched to manual mode via a digital signal, the value of the control output can be preset, for example, to fully open a control valve automatically during a cleaning cycle.

External setpoint selection

The CM50’s control setpoint can be selected via external digital signals, for example, simplifying operation by selecting different setpoints using external push buttons.

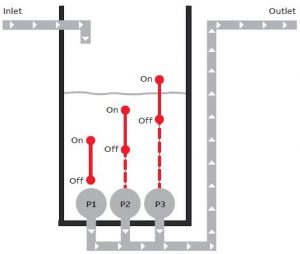

Bank control

Bank control enables improved control of multi-element output devices such as banks of heaters, pumps and fans. Aimed at minimising wear caused by over-use of one specific ‘duty’ device, bank control enables wear to be levelled by sharing duty and assist handling between every device in the bank.

Bank control gives users the choice of either ‘Rotate’ or ‘First In, First Out (FIFO)’ wear-levelling schedules. If required, bank control can be combined with PID control, assigning the PID output signal to the bank control function.

Bank control gives users the choice of either ‘Rotate’ or ‘First In, First Out (FIFO)’ wear-levelling schedules. If required, bank control can be combined with PID control, assigning the PID output signal to the bank control function.

Bank control can also be utilised when split output control is configured. For example, when two variable speed pumps are being controlled in a duty assist configuration. Each time both pumps are stopped the duty and assist outputs are alternated.

ABB CM50 PDF Downloads

Related Products

ABB CM10 Universal Process Controller 1/8 DIN

The ABB ControlMaster CM10 is a flexible, universal 1/8 DIN PID process controller.

ABB CM30 Universal Process Controller 1/4 DIN

The ABB ControlMaster CM30 is a highly versatile, universal 1/4 DIN PID process controller.

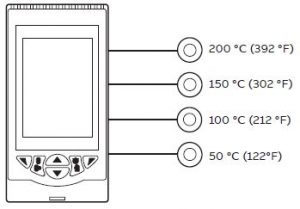

ABB C50 1/16 DIN Universal Controller

The ABB C50 Universal Controller is a simple “indicating switch” suitable for a wide range of applications including OEMs, consumer foods, ovens, HVAC and utilities.Contact

- 01706 216667

- 01706 216681

- instruments@whgood.co.uk